Ultra-high tensile steel

Ultra-high tensile steel

Why is it called ultra-high tensile steel?

Ultra-high tensile steel is a type of alloy steel that is known for its very high yield point tensile strength, typically above 690MPa. This makes it possible to withstand a large amount of stress without deformation or permanent damage. The high yield point tensile strength is due to the addition of alloys such as chromium, molybdenum, silicon, manganese, nickel and vanadium, which improves the tensile strength and durability of steel.

Ultra-high tensile steel with yield strength of not less than 690MPa It can be produced through two different processes: Quenched & Tempered and Thermo Mechanical Control Process (TMCP). Both processes aim to increase the strength and ductility of steel. But different methods are used to achieve these properties.

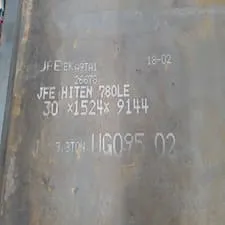

- Ultra High Tensile Steel, Quenched & Tempered: This process involves heating the steel to high temperatures. Hardening produces an unstable martensite structure, and subsequent restoration adjusts the unstable martensite to be more stable, thus achieving the desired level of hardness and toughness. Leong Jin has the grade JFE-Hiten780LE available.

- Ultra-high tensile steel with a Thermo Mechanical Control Process (TMCP): TMCP is a process that combines controlled rolling with controlled cooling to produce steel with a fine microstructure. The steel is rolled at high temperatures and then cooled down rapidly. This process resizes the grain and increases the strength and toughness of the steel without the need for additional heating or restoration. TMCP steels usually have good weld ability and formability due to their improved microstructure. Leong Jin has PERFORM700 grades available.

The main differences between Q&T and TMCP steels are:

- Microstructure: Q&T steels have a martensitic microstructure, while TMCP steels have a fine ferrite or bainite microstructure.

- Production Process: Q&T It involves the post-rolling heat hardening process, while TMCP incorporates heat hardening during the rolling process.

- Features: Both processes aim to improve strength and ductility, but TMCP steels also focus on good weld ability and formability.

- Applications: Q&T steels are often used in applications that require high wear resistance. While TMCP steel is suitable for structures that require good toughness at low temperatures.

Both types of steel are used in applications that require high strength and durability, such as in construction. The choice between Q&T and TMCP will depend on the specific requirements of the application, including mechanical properties, weld ability, and cost considerations.